Improving Iron Ore Fragmentation With Varistem

Varistem® Blast Stemming Plugs Trials Iron ore fragmentation plays a crucial role in the efficiency of mining operations, directly impacting the performance of processing plants.

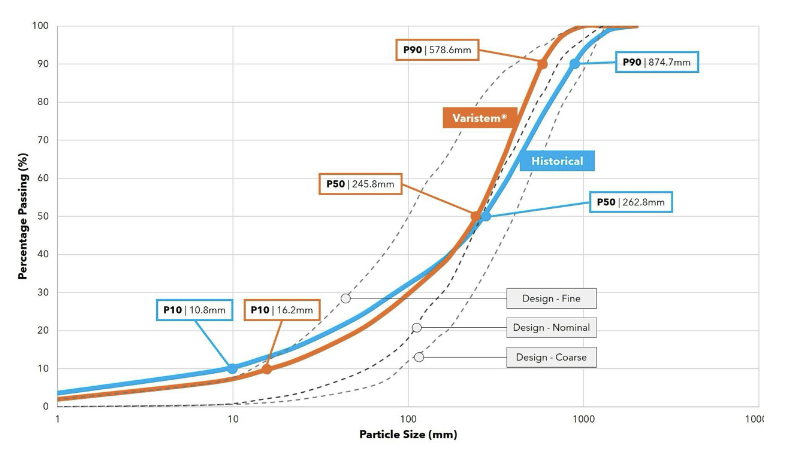

Iron ore fragmentation plays a crucial role in the efficiency of mining operations, directly impacting the performance of processing plants. The following study focuses on the improvement of particle size distribution (PSD) through the use of Varistem® blast stemming plugs in iron ore mines. By conducting comprehensive trials and comparing historical data with the results obtained from using Varistem®, this analysis aims to demonstrate the benefits of optimized fragmentation in enhancing plant performance and reducing operational costs.

In order to understand and analyse the particle size distribution (PSD) data and how it fits into the plant design curve the following needs to be noted.

The analysis will be done comparing the average of the historical blast results, and the Varistem® blast results to the Nominal curve (the most optimal curve)

The analysis will be done comparing the average of the historic blast results, and the Varistem® blast results to the Nominal curve (the most optimal curve). It is important to note that the historic data on Iron Ore Mine Y indicates that the majority of the material is way too

fine, sitting outside of the required envelope or just on the maximum required fines. Varistem® has helped to improve on the by reducing the fines to an extent that it is within the envelope and almost matches the nominal curve for about 60% of the material

The results of the Varistem® trials in both Iron Ore Mine X and Iron Ore Mine Y clearly indicate significant improvements in particle size distribution compared to historical data. The use of Varistem® has led to a reduction in topsize and oversize particles, better conformance to the nominal curve, and a more uniform size distribution overall. These improvements translate to increased efficiency in loading, hauling, and crusher throughput, as well as reduced secondary breakage costs. By aligning the PSD more closely with the plant’s design envelope, Varistem® enhances operational performance, ultimately contributing to more efficient and cost-effective mining processes. This study underscores the value of adopting advanced blast stemming technologies in optimizing ore fragmentation and achieving sustainable mining operations.

Varistem® Blast Stemming Plugs Trials Iron ore fragmentation plays a crucial role in the efficiency of mining operations, directly impacting the performance of processing plants.

Varistem® is a patented blast-stemming plug for mining, quarrying and civil blastingapplications. The plugs contain blast energy for longer, resulting in a range of benefitsdepending

Executive summary Trial setup Information and scaled depth Results – block movement & stemming activity Results – muckpile comparison Results – cast analysis The main