Flyrock Reduction at Coal Mine Using Varistem® Stemming Plugs

Varistem® Stemming Plugs Trial Summary Introduction Flyrock is a significant safety and environmental concern in coal mining, particularly when blasting occurs near inhabited areas. This

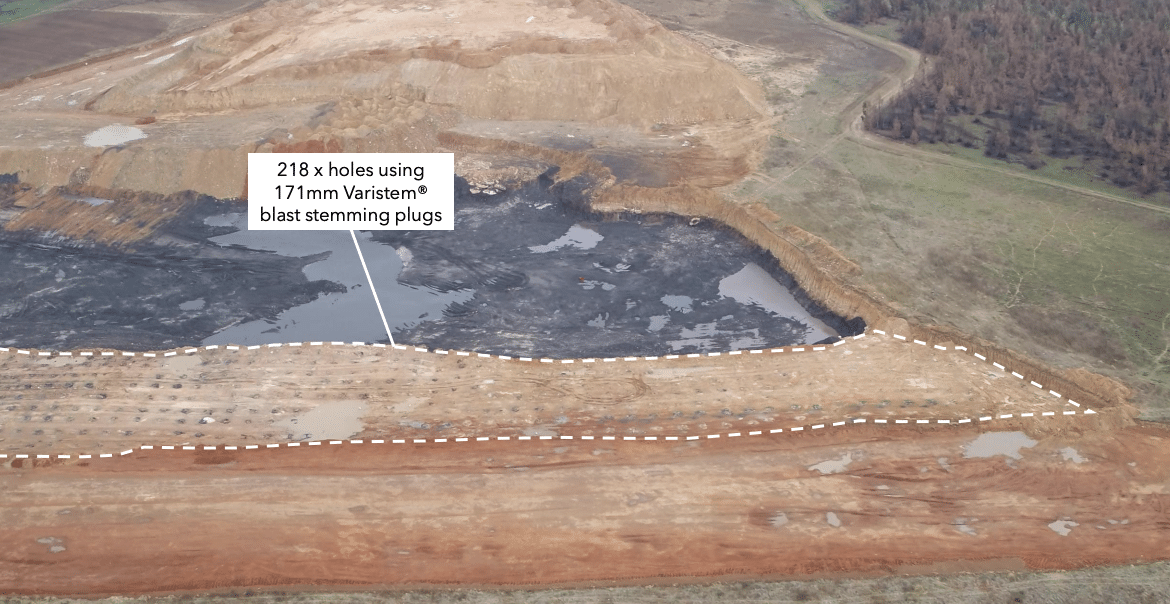

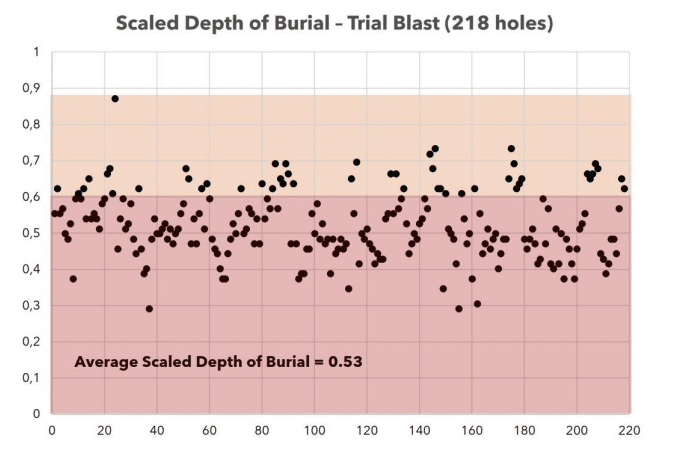

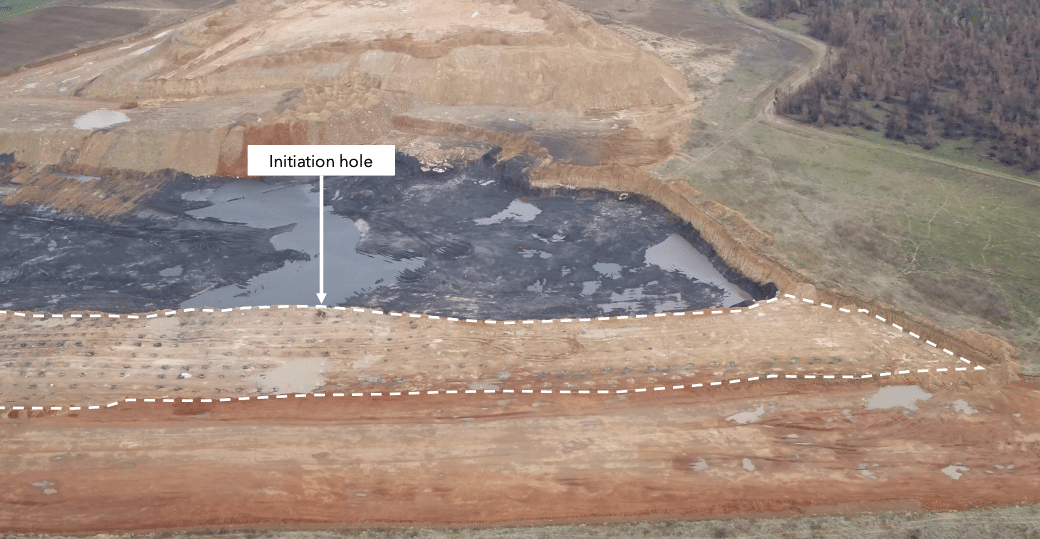

Flyrock is a significant safety and environmental concern in coal mining, particularly when blasting occurs near inhabited areas. This study aims to evaluate the effectiveness of Varistem® stemming plugs in reducing flyrock at Coal Mine X. The trial was conducted near a neighboring farm within a 500m blast radius, presenting a challenging scenario due to the proximity of the blast. By utilizing actual drilling and charging data to calculate the Scaled Depth of Burial (SDoB), this trial sought to assess whether Varistem® could effectively minimize flyrock, noise, and airblast, thereby enhancing safety and operational efficiency.

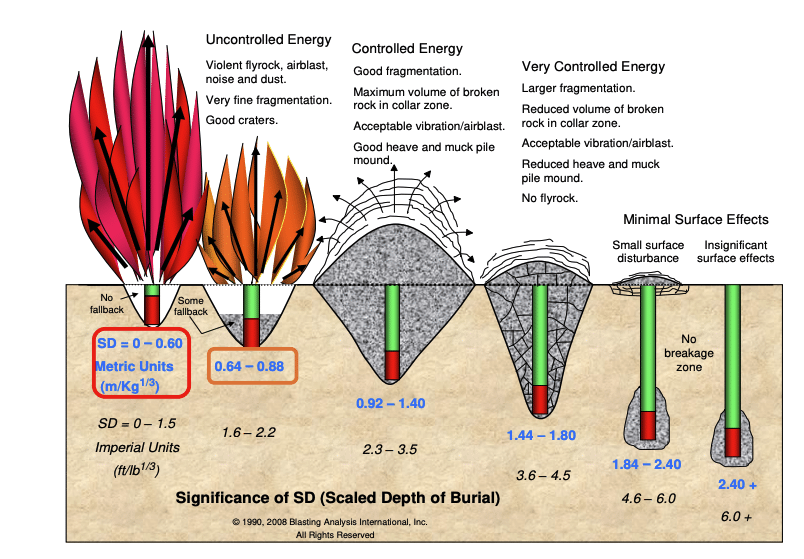

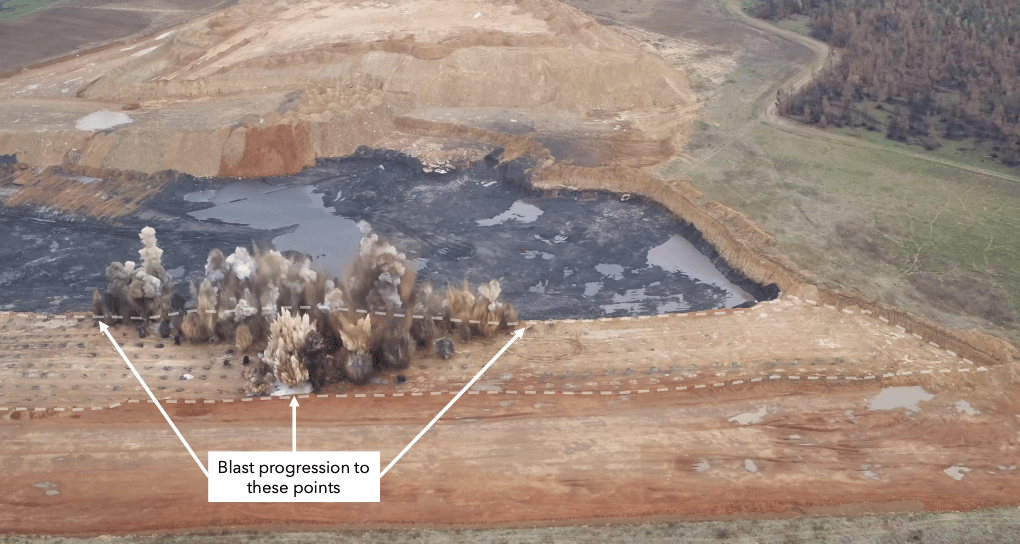

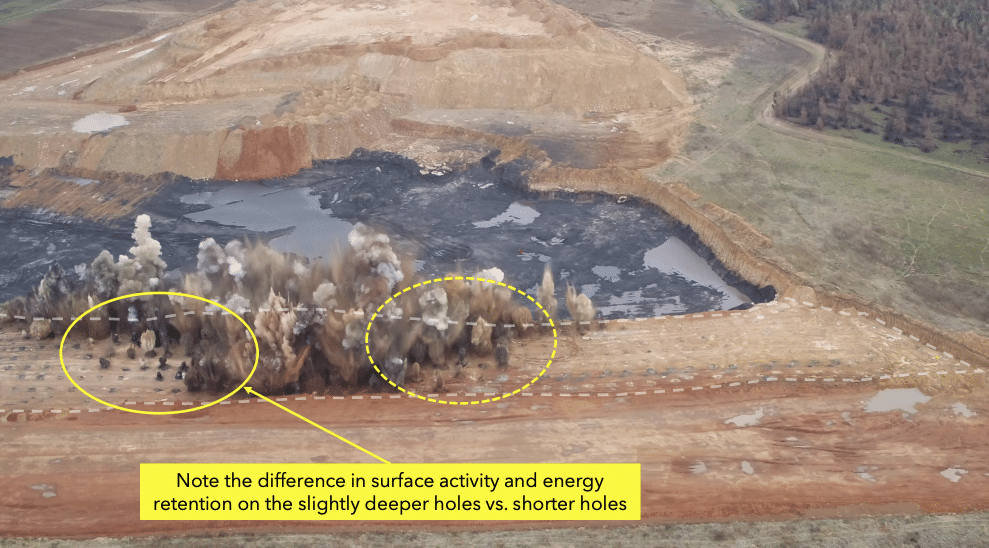

Based on the scaled depth of burial values, the expectation would be that a large number of holes during this trial blast will produce violent flyrock. Note: SDoB values were calculated using actual charging and drilling data. For access to the calculation sheet, please contact us.

The trial at Coal Mine X demonstrated the efficacy of Varistem® stemming plugs in significantly reducing flyrock, even under challenging conditions with a low average SDoB of 0.53. Contrary to theoretical expectations of violent flyrock, the blast results showed excellent energy retention, with flyrock reaching no further than 100m from the blast site. The use of Varistem® plugs not only mitigated violent flyrock but also contributed to a more controlled blast, producing a “violent heave” rather than dangerous flyrock. These findings suggest that Varistem® effectively increases SDoB values by retaining more energy within the rock mass, enhancing safety and operational outcomes. While further comparisons with non-Varistem® blocks are recommended for definitive conclusions, the results of this trial are promising and affirm the potential of Varistem® stemming plugs in improving blast safety and efficiency in coal mining.

Varistem® Stemming Plugs Trial Summary Introduction Flyrock is a significant safety and environmental concern in coal mining, particularly when blasting occurs near inhabited areas. This

Introduction and Project Background ERG Industrial conducted a Varistem® stemming plug pilot project at a South African underground platinum mine between May 2024 and June

Varistem® is a patented blast-stemming plug for mining, quarrying and civil blastingapplications. The plugs contain blast energy for longer, resulting in a range of benefitsdepending