Varistem® Blast Design Adds $10 Million Annually

Introduction Blasting is the first step in the mining value chain, and any positive impacts made during blasting result in exponential downstream gains. In the

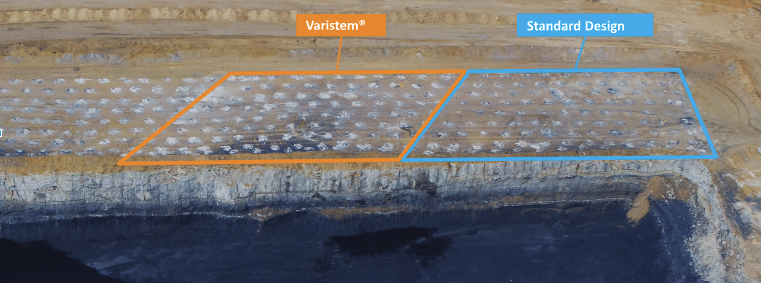

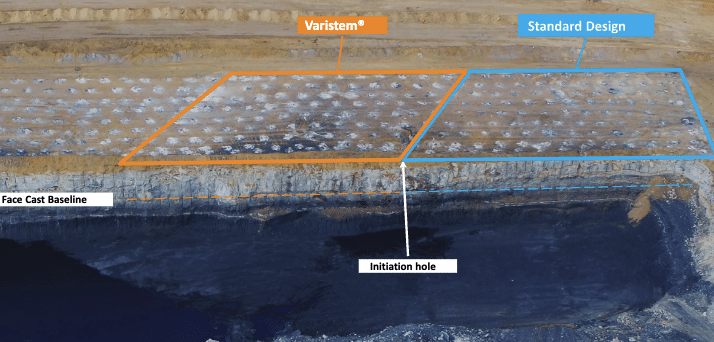

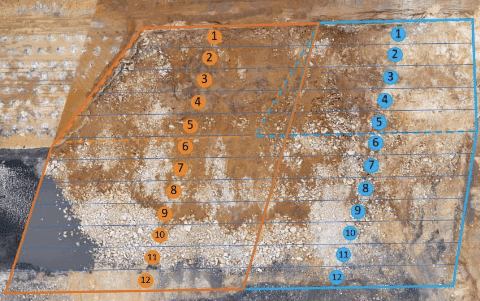

The main focus of the trial was to establish the improvement of the cast by utilizing Varistem® Plugs. The analysis is achieved through the use of drones equipped with survey sensors:

ENAEX Summary: Five drilled blast holes on the crest, initiated directly after one another from the initiation point, were identified and instrumented to measure the velocity of detonation of the Vertex A explosives type. In three of these holes stemming plugs were inserted and an average VOD of 5 774.00m/s was measured. The remaining two holes were stemmed with drill chips as usual. The VOD trace in the unplugged hole indicated deflagration which possibly could have been a result of column shift (as witnessed in borehole tracking results of hole #5). The geology around the instrumented hole was cracked and in-situ material badly damaged as a result of back break from the previous blast. The VOD results captured in this hole is not a good representative result for the given explosives type and geology.

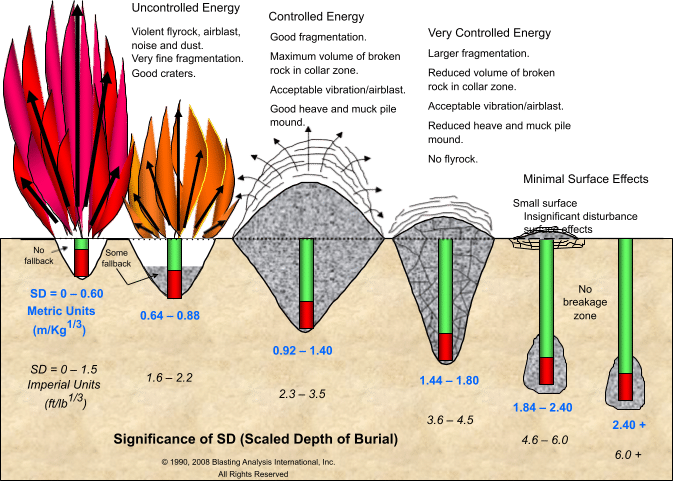

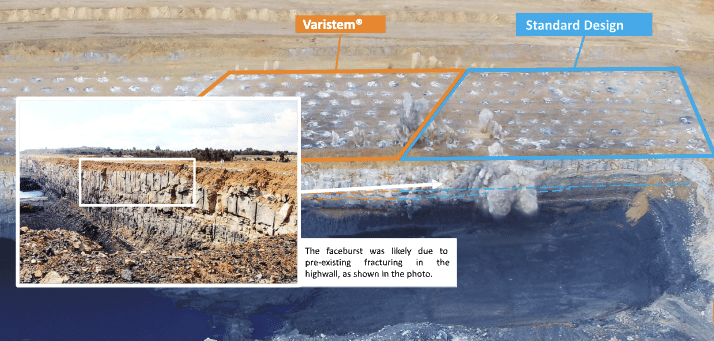

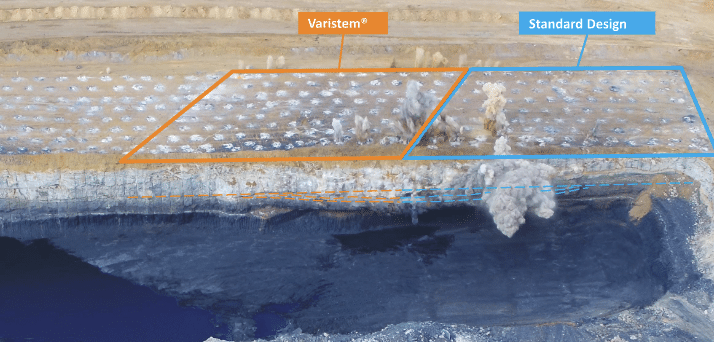

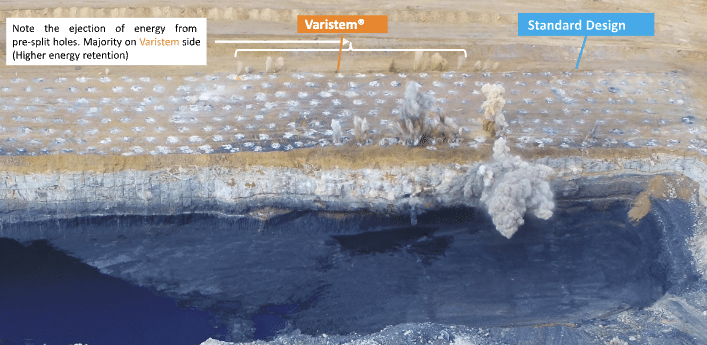

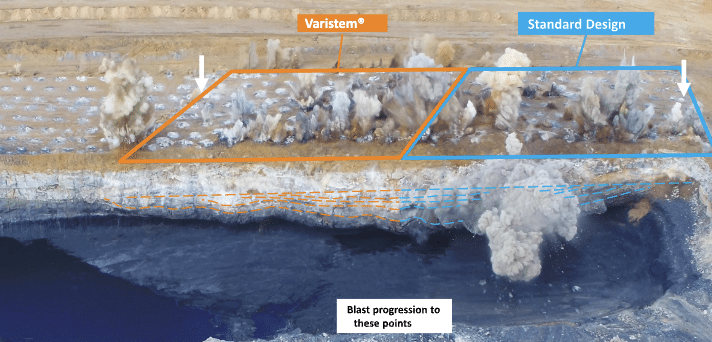

From the visual analysis conducted, it appears that the holes on the Varistem® side of the block had a longer time-to-stemming-movement as compared to the non-Varistem® side of the block. This can be seen by comparing the visuals of the surface of the block at different points in time. Although the block still showed a number of ejections, no significant flyrock was present. The type and number of ejections was expected, based on the scaled depth of burial values.

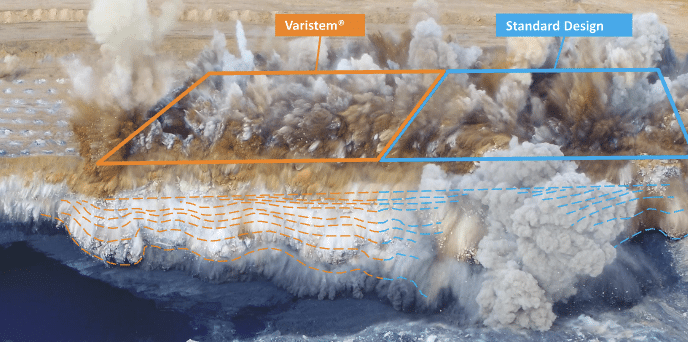

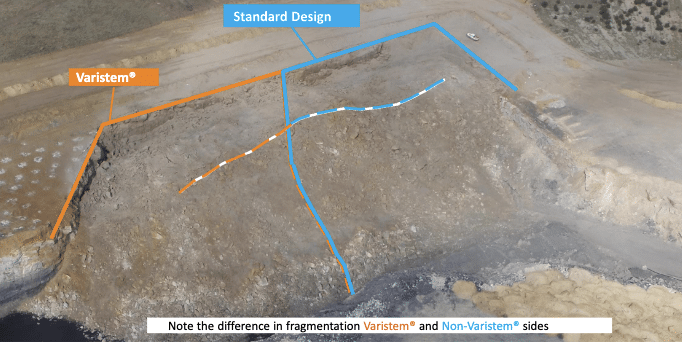

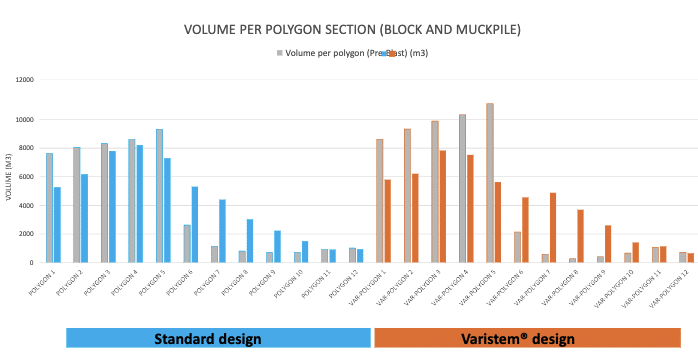

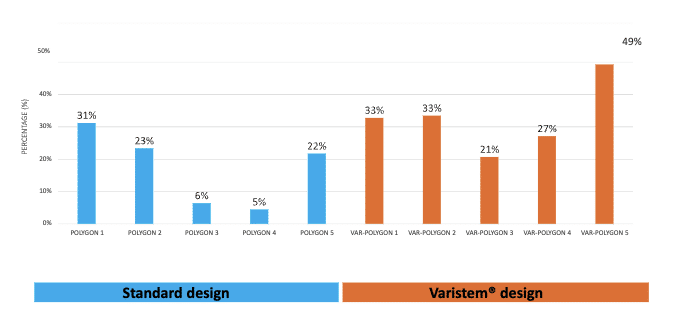

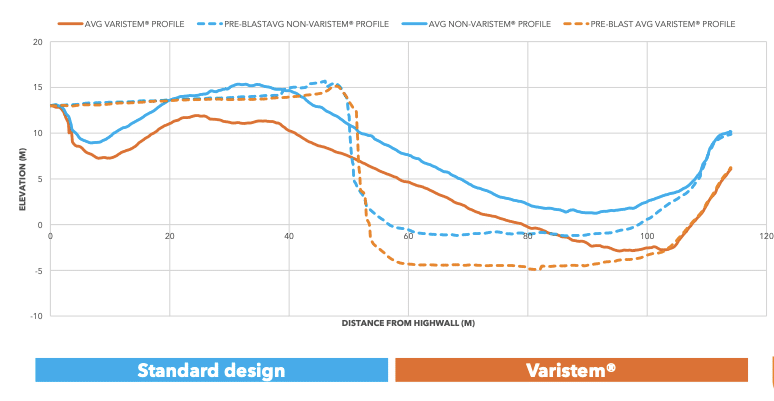

When looking at the shape and peak of the muckpile following the blast, it is evident that the Varistem® side of the block had a deeper and wider power trough, and a muckpile peak that was further away from the highwall. In terms of fragmentation, visual observations reveal that the fragmentation was finer on the Varistem® side of the block.

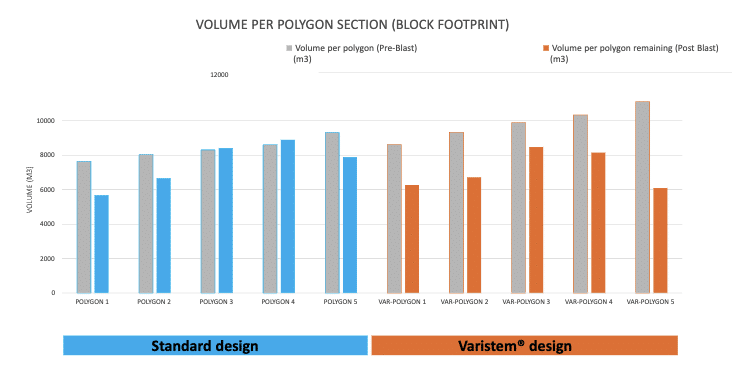

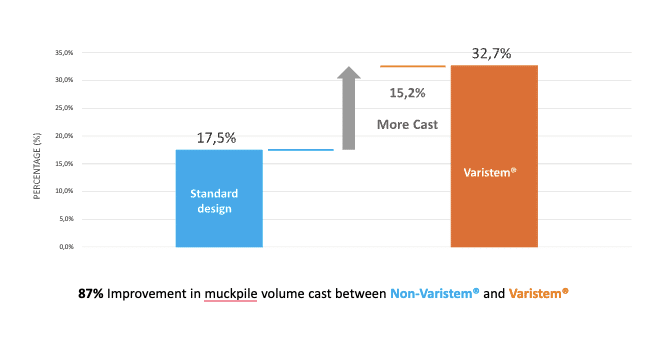

The cast analysis showed that the portion of the block that used Varistem® cast the material, on average, 87% further than the portion that did not use Varistem®. Although this is a significant increase, it must be noted that there were some differences in timing (due to the sensitive nature of the blast) that may have had an impact in the percentage of material cast by the non-Varistem® side. However, it is unlikely that this difference was wholly responsible for the entire difference of 87%, and it is likely that there would still have been a significant difference with a “normal” timing pattern.

A total of 5 holes were used for VOD measurements (3 x holes with Varistem®, 2 x holes without Varistem®). On average, the Varistem® holes had a VOD of 5 774.00 m/s, with a maximum VOD of 7 420.8 m/s. Of the 2 x non-Varistem® holes, only one registered during the blast, and this hole was deemed to be not representative due to a likely column shift. The 5 x holes selected for the VOD analysis were subject to adverse geology, and thus the conclusion was reached that the VOD results could not be deemed as representative.

Introduction Blasting is the first step in the mining value chain, and any positive impacts made during blasting result in exponential downstream gains. In the

Introduction and Project Background ERG Industrial conducted a Varistem® stemming plug pilot project at a South African underground platinum mine between May 2024 and June

Varistem® is a patented blast-stemming plug for mining, quarrying and civil blastingapplications. The plugs contain blast energy for longer, resulting in a range of benefitsdepending