Flyrock Reduction at Coal Mine Using Varistem® Stemming Plugs

Varistem® Stemming Plugs Trial Summary Introduction Flyrock is a significant safety and environmental concern in coal mining, particularly when blasting occurs near inhabited areas. This

Blasting is the first step in the mining value chain, and any positive impacts made during blasting result in exponential downstream gains. In the case of manganese mining, reducing the amount of fines produced during blasting can lead to astronomical financial gains. This case study from a South African manganese mine demonstrates how a minor change to blast design resulted in an additional +$10 million per year in value.

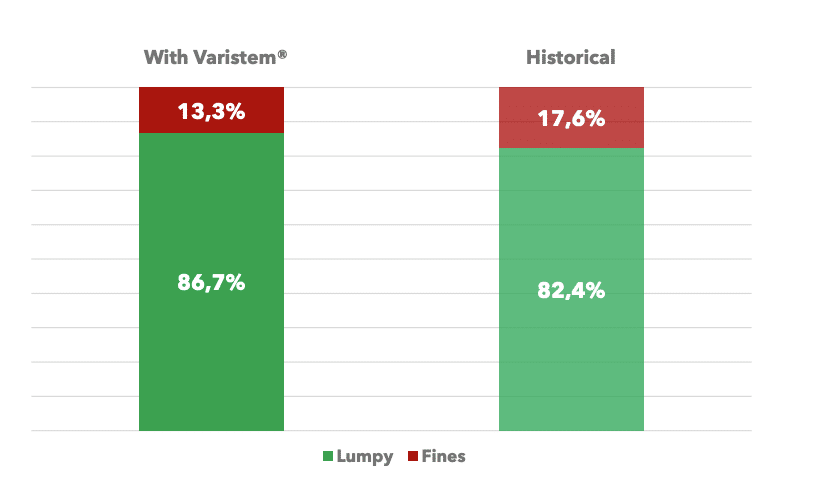

Manganese mines typically sell two categories of products, albeit at different grades:

Fines are usually priced at a discount of around 30% compared to lumpy products. Therefore, reducing fines through blasting increases the amount of lumpy product available for sale at a higher price.

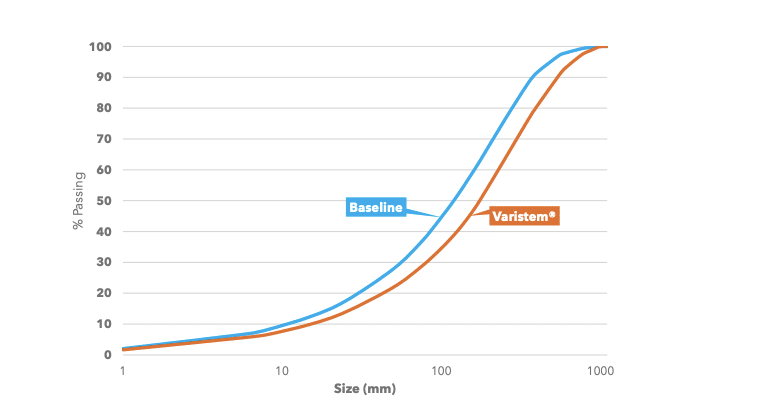

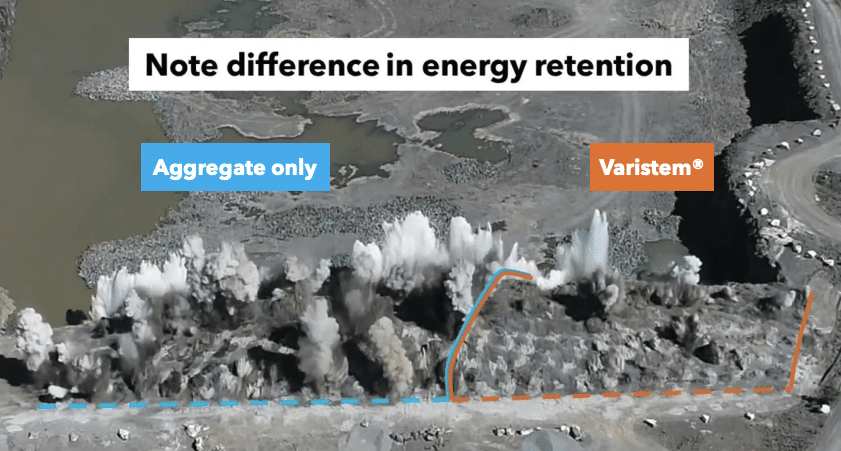

At Manganese Mine X in South Africa, we focused on improving energy retention and distribution during blasting using Varistem® stemming plugs. This resulted in a significant reduction in fines and an increase in lumpy products.

Manganese Mine X blasts approximately 6.9 million tons of manganese per year, across different grades and corresponding prices. By reducing fines and increasing lumpy products, the mine achieved substantial financial gains:

With a straightforward change in blasting design and the use of Varistem® stemming plugs, Manganese Mine X significantly reduced the production of fines, resulting in substantial net financial gains. This case study highlights the profound impact of optimizing blasting techniques in the mining industry.

By focusing on improved energy retention and distribution during blasting, and using Varistem® stemming plugs, significant financial gains were achieved at Manganese Mine X in South Africa. This simple change in blast design not only increased the proportion of lumpy products but also added an additional +$10 million per year in value.

Varistem® Stemming Plugs Trial Summary Introduction Flyrock is a significant safety and environmental concern in coal mining, particularly when blasting occurs near inhabited areas. This

Executive summary Trial setup Information and scaled depth Results – block movement & stemming activity Results – muckpile comparison Results – cast analysis The main

Introduction With chemical energy still being one of the most cost-effective means to reduce the size of rock to liberate strategic minerals and metals, blasting